3 hours

I've done a few engine runs now, just trying to make some adjustments to the AeroInjector, and make sure everything is looking alright. I have been following the AeroInjector manual, as well as Jeff Schultz's method, explained here:

Anyway, so far I'm using the 2.5 needle and I've adjusted it about 3/4 turn toward lean from the start point, and I think it's in the ballpark.

I also fixed my throttle friction issue from before. I just bought a rubber fender washer from Home Depot and added it between the throttle lever and the bracket, and now the friction holds it pretty well.

Anyway, as I felt like I was getting the setting close to nearly correct, I tried doing a full throttle run. I think this is where everything will really start to show up. Here's what I observed:

(((CAVEAT: I still don't have the correct propeller installed so I will have to re-address all of this later anyway)))

1. I did not get the full 40 in-Hg manifold pressure at full throttle, although the static RPM seemed good. The Aerovee manual says you should get 3000 RPM static (with the right prop), and the max manifold pressure is 40". I got about 3150 RPM, which makes sense because the prop is a little too fine. However I only got up to a max of 34.3" manifold pressure. I'm not sure if I should expect to get the full 40" static; I will ask Sonex. I will definitely examine this more once the final prop is installed.

2. EGT's go up fast at full throttle without the plane moving! I didn't want to spend any more time than I needed to at full throttle because I knew the engine would get hot, but it really does heat up quick. Looking at the data that the G3X recorded, I spent about 25 seconds at full throttle, and the EGTs quickly rose to about 1200 F, and then gradually climbed to 1300 F. I did a quick leaning test, pulling the mixture out until the engine stumbled, and in those few seconds the EGTs climbed just to the limit of 1400 F. That was as far as I wanted to take it anyway, so as soon as the engine stumbled and the EGTs hit the limit I pushed it back to full rich and then pulled the throttle back to idle so everything could cool back down. The AeroInjector manual says that what you want is an EGT rise of 90-100 from full rich to peak lean at full throttle, so I think I'm pretty close. Probably close enough to fly with it, but I'll repeat the test again with the correct prop before I call it good!

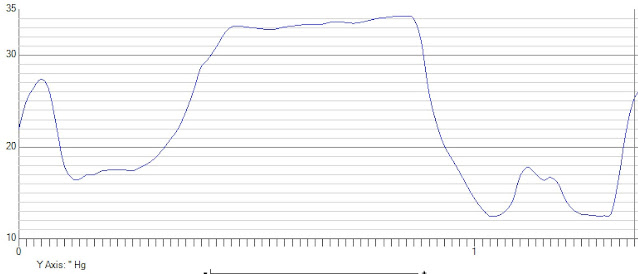

Here is some data that I recorded. The graphs, in order, are RPM, manifold pressure, fuel flow, and EGTs.

You can see on the RPM plot where I ran it up to 3150 RPM, and the small dip, rise, and big fall at the end is where it finally was lean enough to stumble, then I pushed it back to rich, and then immediately pulled it back towards idle.

On the manifold pressure chart, you can actually see the boost increase a a little bit as I started leaning, which makes sense as somewhere between full-rich and too lean is probably where the optimal power setting is.

The fuel flow chart shows pretty clearly where I actually started leaning. At full throttle/full rich it was burning about 7.2 GPH, and then as I gradually leaned it out it made it down to 5.5 GPH which was where the engine finally stumbled.

The EGT chart shows the full throttle/full rich temps around 1200-1300, then a pretty quick rise to 1400 as I did my leaning test.

This data is all pretty useful to have, as I didn't really catch any of this while I actually did it... I was just trying to not overheat the engine! The G3X records pretty much everything, once per second, and dumps it into a CSV spreadsheet. I used the Flight Data Viewer software to view the data, which is a lot easier than just doing it in excel, although that would be possible. The software is available here:

I did find one more issue during all of this too; the G3X is not recording any engine time! By now I've ran it for at least a few tenths, but the G3X still says 0.0 hours. I'm pretty sure I know why. When I switched from the original RPM input to my Honeywell sensor I tried to extract the RPM pin from the connector on the GEA 24, and I messed up that one socket on the connector. So I just plugged the new RPM sensor into the RPM2 position. It works fine, but oddly I think the G3X only counts engine time when the RPM1 value is above the minimum. I'm pretty sure I will need to replace that connector so I can go back to using RPM1!